INTRODUCTION:

There are many companies who provide equipment for making diagnostic LFAs. The LFA device is a test strip inside a plastic housing. This housing can have two or more ports for sample analysis. The strips have five components which include: 1) plastic backing with adhesive and release liner, 2) sample pad, 3) conjugate pad, 4) nitrocellulose pad, and 5) cover layers over the composite device. The materials are supplied in a roll, sheet or strip formats. The membrane is already converted for lamination onto the plastic backing. Other materials are converted to the correct widths for processing and lamination before, or after, reagents are process. In the next several short notes, I will present how one company, BioDot, makes their LFA devices, using information and product photos taken from their website https://www.biodot.com/lateral-flow/.

MEMBRANE:

Dispensing test and control lines onto the membrane can be done before or after lamination. Blocking reagents can be dispensed in parallel with the test and control, or afterwards. The typical dispensing onto the membrane is in a strip format using XY tables with bare membrane before lamination or maters strips where the membrane has been laminated onto the plastic backing. The strip length is typically 300-500 mm. The blocking reagent can also be dispensed using a third dispense channel in parallel with the test and control lines. This dispensing can also be done on a reel-to-reel system using a roll format where the membrane is unbacked or pre-laminated to the backing material. Line dispensing can be done with a contact or non-contact dispensing system. The non-contact is preferable, as contact dispensing leaves a small indentation on the membrane surface that degrades the quality of the dispensed line.

CONJUGATE AND SAMPLE PADS:

Two pads are typically processed using impregnated sheet stock, followed by drying, cutting to width, and lamination to the backing card. Web materials can be impregnated with an in-line reel-reel machine. The reagent is very accurately dispensed along the lamination direction so that at each cut the lateral flow strip will have the same volume or dried reagent.

DISPENSING AND IMPREGNATION PRODUCTS:

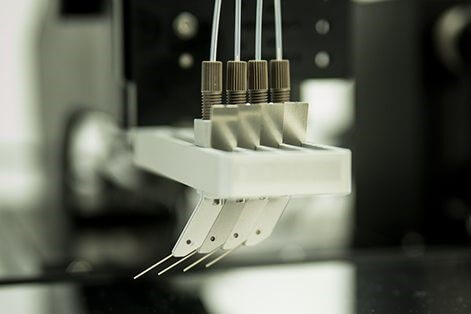

BioDot provides a number of dispensing and impregnation options for processing lateral flow test strips formats that can be integrated into different platforms. One such system is their Frontline HFTM platform, shown below.

The Frontline HFTM system is ideal for printing lines on membranes and other substrates for rapid test, immunoblots and biochips. However, since the dispensing tip rides on the substrate surface, it leaves a small indentation on the membrane surface that degrades the quality of the dispensed line. For this reason, it is not preferable for use with a lateral flow system.

Continue to next article: Manufacturing of Lateral Flow Assays (Part 2)